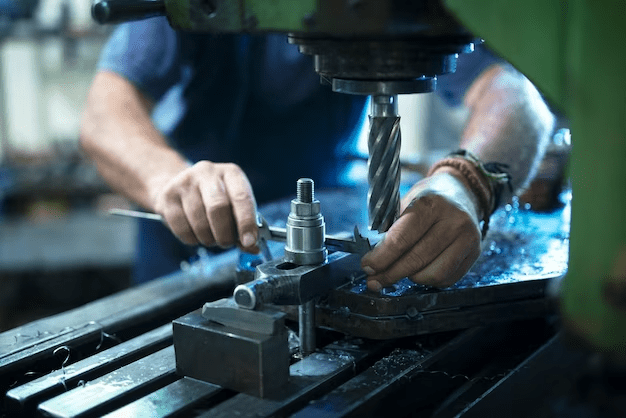

In the quest for manufacturing excellence, the incorporation of Artificial Intelligence (AI) for quality control is a strategic move reshaping how products are monitored and ensured to meet the highest standards.

Data Mastery: AI’s Swift Analysis in Real-Time

AI for quality control leverages advanced algorithms to process vast amounts of data swiftly. This capability allows for comprehensive inspections at various production stages, providing a robust and reliable quality control mechanism.

Predictive Maintenance: AI’s Proactive Approach

The implementation of AI introduces predictive maintenance, minimizing downtime and contributing to overall efficiency. By analyzing historical data, AI systems predict potential equipment failures, empowering manufacturers to take proactive measures and reduce costs.

Consistency Elevated: AI’s Role in Uniform Product Quality

AI-driven quality control ensures heightened product consistency. Free from human limitations, AI systems guarantee uniformity and adherence to quality standards, enhancing the reputation of manufacturers and building trust with customers.

Conclusion

In conclusion, the integration of AI for quality control represents a monumental leap forward for the manufacturing industry, offering increased efficiency, reduced costs, and an overall elevation in the quality of manufactured goods.